Stamping

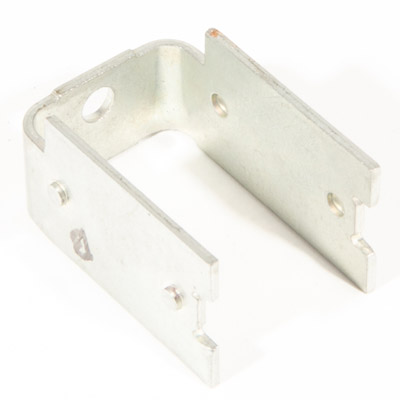

Whether the need is for 100,000 parts or into the millions, Dove Die & Stamping’s commitment is precision parts made to exact customer specifications using progressive die stamping. Specializing in coil fed processes, the company stamps component parts and also produces stamping assemblies. Using single hit and automatic presses that are 75-400 tons, this specialization in progressive die stamping allows for precise production and minimal waste, enabling efficient use of raw materials.

From carbon steel to aluminum, brass, and stainless steel, Dove Die & Stamping can precisely form metal parts from thicknesses of 0.03” to 0.25” to get the job done. Quality is at the heart of the business, with inspections conducted throughout the process to ensure customer satisfaction. Dove Die & Stamping employees know what is important to every customer, and strive each day to ensure these needs are met. Value added operations include welding, staking, tapping and clinching.

Products include:

- brackets for timing systems

- chain guides

- brake components

- engine components

- ride control components

- variable cam timing components

- faucet mounting brackets

- valve components

- behind the wall brackets

- mounting plates

- … and more

Once products are stamped, Dove Die & Stamping also has the in-house capabilities for tapping, grinding, deburring, washing, and packaging. Qualified partners can also provide anodizing, plating, and heat-treating services.